- Home

- PLC Control Systems

PLC Control Systems

Should you be looking for PLC Control Systems, then you have come to the right place. Here at Process Automation, we provide a range of PLC Control Systems.

The Programmable Logic Controllers that we provide to businesses are suitable for a number of different industries including the food and beverage industry, the refrigeration and manufacturing industry.

What’s more when you choose Process Automation to supply and install your PLC Control Systems, you can trust that we also offer comprehensive training and support services.

What Is a Programmable Logic Controller?

How do PLCs Work?

- Input and Output - The central processing unit of the PLC stores and processes the data, but the input and output elements are what connect the PLC to the rest of the machine, it is ultimately the input and output elements that provide the data to the central processing unit which generates specific results.

- Communication - PLCs might be required to connect to other systems too, as well as the input and output devices. An example of this might be that the data on the application needs to be exported to the supervisory control and data acquisition system (SCADA). A PLC has a range of communication tools and protocols to ensure they can communicate with other systems and devices if needed.

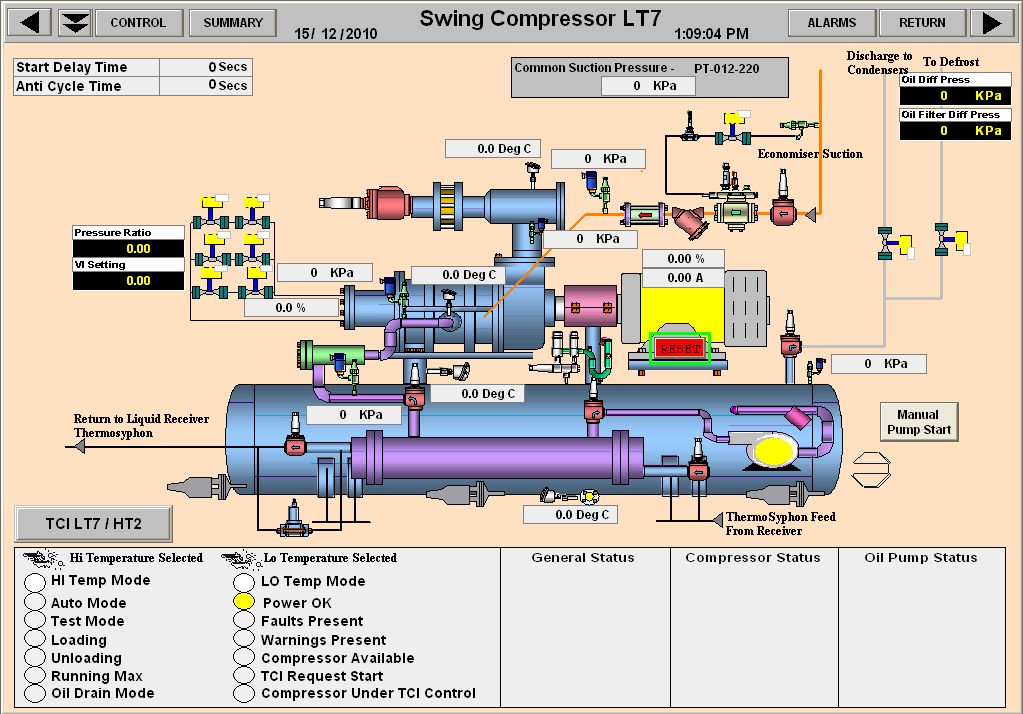

- HMI (Human Machine Interface - a HMI enables PLC users to interact effectively with the machine. You will find the HMI can be a simple display complete with text and keypad, or touchscreen panels. These allow users to review and input data to the PLC almost immediately.

Programmable Logic Controllers

PLCs contain input and output devices compatible with industrial pilot devices and controls; little electrical design is required, and the design problem centres on expressions the desired sequence of operations in ladder logic (or function chart) notation. PLC applications are typically highly customised systems, so the cost of a packaged PLC is low compared to the cost of a specific custom-built designer.

PLC Products we Supply

Here at Process Automation we proud to supply our products to a range of international companies, with spares and support available on a worldwide basis. Some of the international companies that supply PLC control systems to are:

- Allen-Bradley

- Siemens

- General Electric

- Mitsubishi

- Omron

- Toshiba

All of the PLC control systems that we supply, install and support can be standalone or networked utilising DH+ Modbus, Profibus, Devicenet, ASi systems and Ethernet.

PLC Based Control Systems

Over the years the functionality of the PLC has evolved to include sequential relay control, motion control, process control, distributed controls systems and networking. The data handling, storage, processing power and communication capabilities of some modern PLCs are approximately equivalent to desktop computers. PLC-like programming combined with remote input and output hardware allow a general-purpose desktop computer to overlap some PLCs in certain applications.

Why Choose Process Automation for PLC Control Systems

As experts when it comes to supplying and installing a range of comprehensive PLC control systems, you can trust that no matter what your requirements our expert team will be on hand to help you. We have been providing quality PLC products to a range of national and international clients for a number of years, and have an excellent reputation for the service we provide.